ATH-Heinl Bedienungsanleitung Single Lift 35M

- Text

- Montage

- Zustand

- Maschine

- Schraube

- Produkthersteller

- Druckfehler

- Rechte

- Urheberrecht

- Technische

- Vorbehalten

Lowering Problems Check

Lowering Problems Check cable connection Safety catches do not respond Check electromagnets, replace if necessary Relieve the catches by lifting Defective control relay Check control relay Obstruction under platform Remove obstruction Lifting platform does not lower Hose rupture protection Lift the platform briefly and triggered press "DOWN" again Lowering valve is not activated Check electrical connection Defective lowering valve solenoid Replace solenoid Defective lowering valve Replace Valve for lowering speed set incorrectly Set If the errors cannot be rectified, lower the lifting platform with the emergency lowering screw and contact our service team Contaminated lowering valve Clean lowering valve Platform lowers too slowly or Valve for lowering speed set jerkily Set incorrectly Leaking hydraulic connections Retighten connections if necessary Leaking hydraulic lines Replace hydraulic line Lifting platform lowers by itself Leaking hydraulic cylinder Replace and clean the seals of the hydraulic system Dirty or defective lowering valve Clean or replace the lowering valve Leaking check valve Clean or replace Other Problems Lifting platform does not raise or lower synchronously Product shows (heavy) rust damage Abnormal motor volume Circuit breaker has been activated Air in hydraulic circuit Synchronising cables not tight enough Damage or lack of corrosion protection, possibly maintenance Dirty oil filter Air in hydraulic circuit Contaminated hydraulic oil Check the contact on the contactor Check the capacity of circuit breakers Check for damage to the cable Bleed the hydraulic circuit Adjust the tension or the synchronicity Remove rust, clean and restore surface. Clean the oil filter Bleed the hydraulic system Change the hydraulic oil Replace the contactor Replace the fuses Replace the cable ALWAYS USE ORIGINAL PARTS AND ACCESSORIES. ® Copyright ATH-Heinl GmbH & CO.KG, All rights reserved / Misprints and technical changes reserved / Release date: 2022-07 Product manufacturer ATH-Heinl GmbH & CO.KG - 31 -

4.6 Maintenance and Service Instructions All maintenance and service work should be carried out at least according to the maintenance schedule COMPRESSED AIR MAINTENANCE UNIT (Partial stock if necessary for the activity) SETTING THE WORKING PRESSURE: • Check the working pressure displayed by the manometer (1). This must correspond to the technical data. • The working pressure can be adjusted with a pressure regulator (A). • Pull the pressure regulator upwards to make adjustments. • Turn the knob clockwise to increase the pressure in the machine, turn it counter clockwise to decrease. C A 1 OILER • Check the oil level in the oil reservoir (3). • Remove the oil reservoir. • Now refill the tank with a pneumatic oil with a viscosity of SAE20. • Check the injection quantity of the oil through the viewing glass (4). • Generally, the screw must be closed completely in a clockwise direction and then opened again about ¼ to ½ turn by turning it counter clockwise. 4 3 B 2 WATER SEPARATOR • Check the water level in the separator (2). • Water is drained when the valve (B) is opened. ® Copyright ATH-Heinl GmbH & CO.KG, All rights reserved / Misprints and technical changes reserved / Release date: 2022-07 Product manufacturer ATH-Heinl GmbH & CO.KG - 32 -

- Seite 1 und 2:

Deutsch English Polskie Français

- Seite 3 und 4:

Inhalt 1.0 EINLEITUNG .............

- Seite 5 und 6:

1.2 Beschreibung Hubsäule In der H

- Seite 7 und 8:

1.3 Bedienung Buzzer Taster Heben u

- Seite 9 und 10:

Zur sicheren Arbeit sind ordnungsge

- Seite 11 und 12:

Traglastverteilung Q Gesamtgewicht

- Seite 13 und 14:

2.0 INSTALLATION Die Maschine muss

- Seite 15 und 16:

2.4 Standort Die Maschine sollte vo

- Seite 17 und 18:

2.9 Montage Diese Anleitung ist nic

- Seite 19 und 20:

Montage Grundplatte Montieren Sie d

- Seite 21 und 22:

Montage der Hubeinheit (Fahrset) Mo

- Seite 23 und 24:

Fertigmontage Montieren Sie die Fro

- Seite 25 und 26:

3.2 Grundsätzliche Hinweise Die He

- Seite 27 und 28:

. Park-Position • Ab einer Hubhö

- Seite 29 und 30:

Mindestanforderung für LKW Montier

- Seite 31 und 32:

4.5 Fehlersuche / Fehleranzeige und

- Seite 33 und 34: 4.6 Wartungs- und Serviceanleitunge

- Seite 35 und 36: 5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 37 und 38: 6.2 Elektrik-Schaltplan Q1 Hauptsch

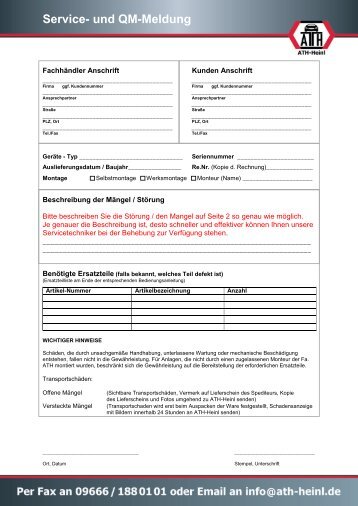

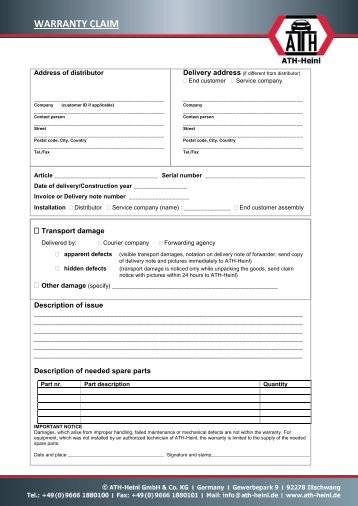

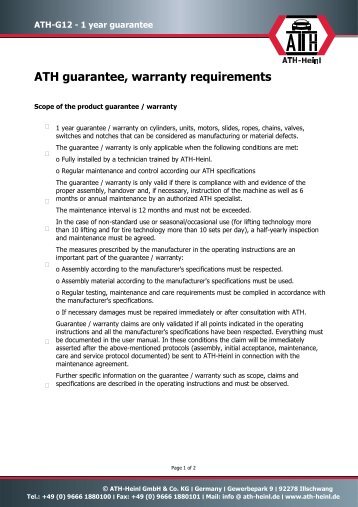

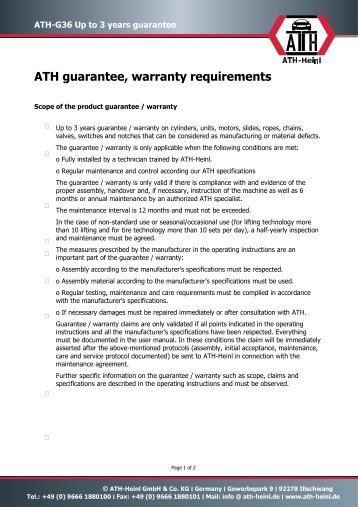

- Seite 39 und 40: 7.0 GARANTIEKARTE Fachhändler Ansc

- Seite 41 und 42: 8.0 PRÜFBUCH Dieses Prüfbuch (ink

- Seite 43 und 44: 8.2 Prüfplan Prüfdatum Typenschil

- Seite 45 und 46: Sichtprüfung (Befugte Sachkundige

- Seite 47 und 48: Sichtprüfung (Befugte Sachkundige

- Seite 49 und 50: Sichtprüfung (Befugte Sachkundige

- Seite 51 und 52: ® Urheberrecht ATH-Heinl GmbH & CO

- Seite 53 und 54: www.ath-heinl.de ATH-Heinl GmbH & C

- Seite 55 und 56: Content 1.0 INTRODUCTION ..........

- Seite 57 und 58: 1.2 Description Lifting column The

- Seite 59 und 60: 1.3 Bedienung Alarm Lift button To

- Seite 61 und 62: ® Copyright ATH-Heinl GmbH & CO.KG

- Seite 63 und 64: Load distribution Q Total weight of

- Seite 65 und 66: 2.0 INSTALLATION The machine must b

- Seite 67 und 68: 2.4 Location The machine should be

- Seite 69 und 70: 2.9 Assembly These instructions are

- Seite 71 und 72: Base plate assembly Install the mid

- Seite 73 und 74: Assembly of the lifting unit (drive

- Seite 75 und 76: Final assembly Fit the front cover

- Seite 77 und 78: 3.2 Basic Information The lifting p

- Seite 79 und 80: . Park-Position • From a lifting

- Seite 81 und 82: Compressed air system Minimum requi

- Seite 83: 4.5 Troubleshooting/ Error Disply a

- Seite 87 und 88: 5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 89 und 90: 6.2 Elektric circuit diagram Q1 Mai

- Seite 91 und 92: 7.0 WARRANTY CARD Dealer address: C

- Seite 93 und 94: 8.0 INSPECTION LOG This inspection

- Seite 95 und 96: 8.2 Inspection Plan Inspection 1 2

- Seite 97 und 98: Visual inspection (authorised exper

- Seite 99 und 100: Visual inspection (authorised exper

- Seite 101 und 102: Visual inspection (authorised exper

- Seite 103 und 104: ® Copyright ATH-Heinl GmbH & CO.KG

- Seite 105: www.ath-heinl.de ATH-Heinl GmbH & C

Unangemessen

Laden...

Magazin per E-Mail verschicken

Laden...

Einbetten

Laden...

LinkedIn

Facebook

Instagram

Youtube

Email

Twitter

Pinterest