ATH-Heinl Bedienungsanleitung M52

- Text

- Reifenmontiermaschine

- Reifen

- Unterlegscheibe

- Maschine

- Washer

- Produkthersteller

- Rechte

- Urheberrecht

- Technische

- Vorbehalten

8.1 Installation and

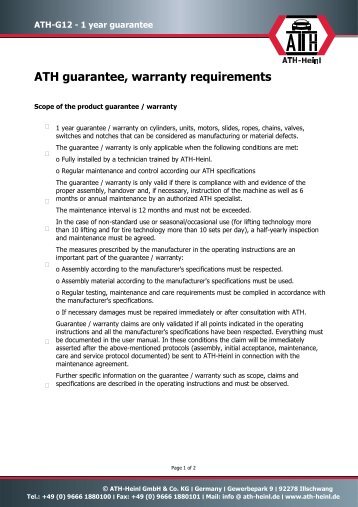

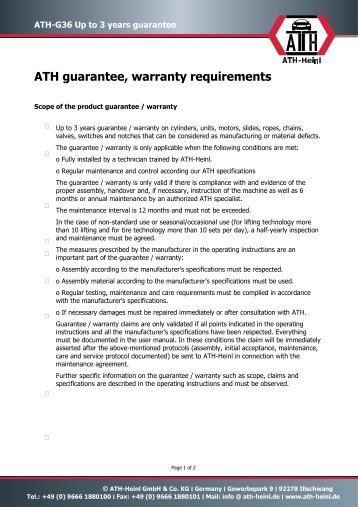

8.1 Installation and Handover Log Site: Company: Street: Town: Country: Device / system: Manufacturer: Type / model: Serial no.: Year of construction: Responsible retailer: The above product has been assembled, checked for function and safety and put into operation. Installation was carried out by: the operator the technical expert The operator confirms that the product type has been set up correctly, that he/she has read and understood all information contained in these operating instructions and the log, and that he/she keeps this documentation accessible to the instructed operator at all times. The operator confirms that after installation and commissioning by a person trained by the manufacturer or an authorised dealer (expert), instruction in the function, handling, safety-relevant specifications, maintenance and care of the machine has taken place, documents, information and specifications of the machine have been provided and the product is working properly. IMPORTANT NOTES: IF THE ABOVEMENTIONED POINTS ARE NOT FULFILLED, THE WARRANTY CLAIM IS EXCLUDED: The warranty is only valid in conjunction with compliance and evidence of proper assembly, handover, and if necessary training, as well as yearly maintenance carried out by an expert authorised by the manufacturer. The interval between services must not exceed 12 months. In case of non-standard use or multi-shift or seasonal use, a bi-annual inspection and maintenance must be arranged. Warranty claims are only recognised if all points in the log and operating instructions have been met, the claim is asserted immediately after detection and this log is sent to the manufacturer along with the maintenance and service logs. Further specific information about the warranty, such as scope, requirements and specifications, are described in the operating instructions and must be observed. Damages and complaints caused by improper handling; failure to maintain and service; use of unsuitable or unspecified assembly, operating, maintenance or service products; mechanical damage; intervening in the unit without consultation or by an unauthorised expert are excluded from the warranty. For systems that have not been installed by an authorised expert, the warranty is limited by agreement of the manufacturer to the provision of the necessary spare parts. Expert name and company stamp if necessary, number and name of retailer Date and expert signature Operator name and company stamp Date and operator signature ® Copyright ATH-Heinl GmbH & Co. KG, All rights reserved / Misprints and technical changes reserved / As of: 2020-03 Manufacturer ATH-Heinl GmbH & CO.KG - 40 -

8.2 Inspection Plan Nameplate Quick reference guide Operating instructions Safety label Operation label Other labels Construction (deformation, cracks) Fixing dowels and stability Condition of concrete flor (cracks) Condition / general condition Condition / cleanliness Condition / care and sealing Condition / liquids Condition / lubrication Condition / aggregate Condition / drive Condition / motor Condition / transmission Condition / cylinder Condition / valve Condition / electrical control Condition / electric buttons Condition / electric switches Condition / electric lines Condition / hydraulic lines Condition / hydraulic screws Condition / pneumatic lines Condition / pneumatic screws Condition / tightness Condition / bolts and bearings Condition / consumables Condition / covers Condition / functions under load Condition / safety-relevant components Condition / electrical safety device Condition / hydraulic safety device Condition / pneumatic safety device Condition / mechanical safety device Condition / functions under load Inspection sticker issued ® Copyright ATH-Heinl GmbH & Co. KG, All rights reserved / Misprints and technical changes reserved / As of: 2020-03 Manufacturer ATH-Heinl GmbH & CO.KG - 41 -

- Seite 1 und 2:

BEDIENUNGSANLEITUNG / OPERATING INS

- Seite 3 und 4:

BEDIENUNGSANLEITUNG ATH M52

- Seite 5 und 6:

1.0 EINLEITUNG 1.1 Allgemeine Infor

- Seite 7 und 8:

4 3 2 1 1 Drücken Sie das Pedal le

- Seite 9 und 10:

1.3.2 Abdrücken eines Reifens Vorb

- Seite 11 und 12:

Das Schaltpedal zum Felgenspannen n

- Seite 13 und 14:

Hebeln Sie nun die Reifenwulst übe

- Seite 15 und 16:

Bei der Montage der zweiten Wulst v

- Seite 17 und 18:

1.4 Technische Daten Außen-Spannbe

- Seite 19 und 20:

2.0 INSTALLATION Die Maschine muss

- Seite 21 und 22:

2.4 Standort Die Maschine sollte vo

- Seite 23 und 24:

2.8 Hydraulischer Anschluss Bevor d

- Seite 25 und 26:

3.0 BETRIEB 3.1 Betriebsanweisung F

- Seite 27 und 28:

4.0 WARTUNG Um einen sicheren Betri

- Seite 29 und 30:

4.3 Hinweise Die Maschine ist, unab

- Seite 31 und 32:

4.6 Wartungs- und Serviceanleitunge

- Seite 33 und 34:

VENTILBLOCK REINIGEN Trennen Sie

- Seite 35 und 36:

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 37 und 38:

6.2 Elektrik-Schaltplan ® Urheberr

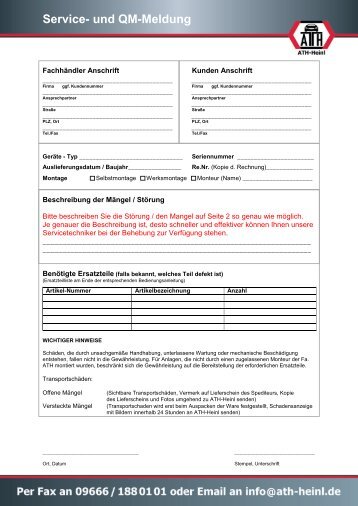

- Seite 39 und 40: 7.0 GARANTIEKARTE Fachhändler Ansc

- Seite 41 und 42: 8.0 PRÜFBUCH Dieses Prüfbuch (ink

- Seite 43 und 44: 8.2 Prüfplan Typenschild Kurzbedie

- Seite 45 und 46: Sichtprüfung (Befugte Sachkundige

- Seite 47 und 48: Sichtprüfung (Befugte Sachkundige

- Seite 49 und 50: ® Urheberrecht ATH-Heinl GmbH & CO

- Seite 51 und 52: OPERATING INSTRUCTIONS ATH M52

- Seite 53 und 54: 1.0 INTRODUCTION 1.1 General Inform

- Seite 55 und 56: 4 3 2 1 1 Press the pedal down slig

- Seite 57 und 58: 1.3.2 Tyre bead breaker Preparation

- Seite 59 und 60: Press down on the gear change pedal

- Seite 61 und 62: In order to lever the lower tyre be

- Seite 63 und 64: When assembling the second bead, fo

- Seite 65 und 66: 1.4 Technical Data Outer clamping r

- Seite 67 und 68: 2.0 INSTALLATION The machine must b

- Seite 69 und 70: 2.4 Location The machine should be

- Seite 71 und 72: 2.8 Hydraulic Connection Before the

- Seite 73 und 74: 3.0 OPERATION 3.1 Operating Instruc

- Seite 75 und 76: 4.0 MAINTENANCE The user must maint

- Seite 77 und 78: 4.3 Notes Regardless of the level o

- Seite 79 und 80: 4.6 Maintenance and Service Instruc

- Seite 81 und 82: CLEANING THE VALVE BLOCK Separat

- Seite 83 und 84: 5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 85 und 86: 6.2 Electric circuit diagram ® Cop

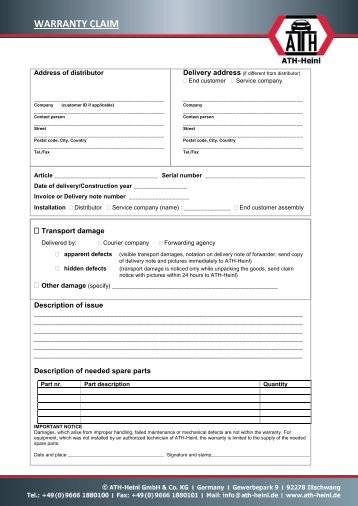

- Seite 87 und 88: 7.0 WARRANTY CARD Dealer address: C

- Seite 89: 8.0 INSPECTION LOG This inspection

- Seite 93 und 94: Visual inspection (authorised exper

- Seite 95 und 96: Visual inspection (authorised exper

- Seite 97 und 98: ® Copyright ATH-Heinl GmbH & Co. K

- Seite 99 und 100: MANUEL D'UTILISATION ATH M52

- Seite 101 und 102: 1.0 INTRODUCTION 1.1 Informations g

- Seite 103 und 104: 4 3 2 1 1 Appuyez légèrement sur

- Seite 105 und 106: 1.3.2 Détalonnage d'un pneu Prépa

- Seite 107 und 108: Appuyez sur la pédale pour serrer

- Seite 109 und 110: Lorsque le démontage est terminé,

- Seite 111 und 112: Pour monter le deuxième talon, pro

- Seite 113 und 114: 1.4 Caractéristiques techniques Pl

- Seite 115 und 116: 2.0 INSTALLATION La machine doit ê

- Seite 117 und 118: 2.4 Lieu La machine doit être tenu

- Seite 119 und 120: 2.8 Raccordement hydraulique Avant

- Seite 121 und 122: 3.0 EXPLOITATION 3.1 Manuel d'utili

- Seite 123 und 124: 4.0 MAINTENANCE Afin de garantir le

- Seite 125 und 126: 4.3 Remarques Quel que soit l'état

- Seite 127 und 128: 4.6 Instructions de maintenance et

- Seite 129 und 130: NETTOYER LE BLOC DE SOUPAPES Dé

- Seite 131 und 132: 5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 133 und 134: 6.2 Schéma électrique ® Droit d'

- Seite 135 und 136: 7.0 CARTE DE GARANTIE Adresse du re

- Seite 137 und 138: 8.0 REGISTRE DE CONTRÔLE Ce regist

- Seite 139 und 140: 8.2 Plan de contrôle Plaque signal

- Seite 141 und 142:

Contrôle visuel (personne qualifi

- Seite 143 und 144:

Contrôle visuel (personne qualifi

- Seite 145 und 146:

® Droit d'auteur ATH-Heinl GmbH &

- Seite 147 und 148:

NÁVOD K OBSLUZE ATH M52

- Seite 149 und 150:

1.0 ÚVOD 1.1 Obecné informace TEN

- Seite 151 und 152:

4 3 2 1 1 Pedál lehce stlačte dol

- Seite 153 und 154:

1.3.2 Odtlačení pláště Přípr

- Seite 155 und 156:

K upnutí ráfku sešlápněte spí

- Seite 157 und 158:

Po demontáži sešlápněte spína

- Seite 159 und 160:

Při montáži druhé patky postupu

- Seite 161 und 162:

1.4 Technické údaje Vnější obl

- Seite 163 und 164:

2.0 INSTALACE Stroj musí v souladu

- Seite 165 und 166:

2.4 Umístění Stroj byste měli p

- Seite 167 und 168:

2.8 Hydraulické připojení Před

- Seite 169 und 170:

3.0 PROVOZ 3.1 Provozní pokyn Firm

- Seite 171 und 172:

4.0 ÚDRŽBA Za účelem zajištěn

- Seite 173 und 174:

4.3 Upozornění Na stroji je nezby

- Seite 175 und 176:

4.6 Návody k údržbě a servisní

- Seite 177 und 178:

ČIŠTĚNÍ BLOKU VENTILŮ Odpoj

- Seite 179 und 180:

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 181 und 182:

6.2 Schéma elektrického zapojení

- Seite 183 und 184:

7.0 ZÁRUČNÍ KARTA Adresa odborn

- Seite 185 und 186:

8.0 KONTROLNÍ DENÍK Tento kontrol

- Seite 187 und 188:

8.2 Harmonogram kontrol Typový št

- Seite 189 und 190:

Vizuální kontrola (povolanou odbo

- Seite 191 und 192:

Vizuální kontrola (povolanou odbo

- Seite 193 und 194:

® Copyright ATH-Heinl GmbH & CO.KG

- Seite 195 und 196:

MANUAL DE INSTRUCCIONES ATH M52

- Seite 197 und 198:

1.0 INTRODUCCIÓN 1.1 Información

- Seite 199 und 200:

4 3 2 1 1 Presione el pedal ligeram

- Seite 201 und 202:

1.3.2 Desmontaje de un neumático P

- Seite 203 und 204:

Presionar el pedal de mando para te

- Seite 205 und 206:

llanta y comience a girar del mismo

- Seite 207 und 208:

Durante el montaje del segundo tal

- Seite 209 und 210:

1.4 Datos técnicos Rango de sujeci

- Seite 211 und 212:

2.0 INSTALACIÓN La instalación de

- Seite 213 und 214:

2.4 Ubicación La máquina deberá

- Seite 215 und 216:

2.8 Conexión hidráulica Antes de

- Seite 217 und 218:

3.0 FUNCIONAMIENTO 3.1 Manual de fu

- Seite 219 und 220:

4.0 MANTENIMIENTO Para garantizar u

- Seite 221 und 222:

4.3 Avisos Independientemente del g

- Seite 223 und 224:

4.6 Guías de mantenimiento y servi

- Seite 225 und 226:

LIMPIAR BLOQUE DE VÁLVULAS Desc

- Seite 227 und 228:

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 229 und 230:

6.2 Esquema de conexiones eléctric

- Seite 231 und 232:

7.0 TARJETA DE GARANTÍA Dirección

- Seite 233 und 234:

8.0 LIBRO DE INSPECCIÓN Este libro

- Seite 235 und 236:

8.2 Plan de inspección Placa de ca

- Seite 237 und 238:

Inspección visual (especialista au

- Seite 239 und 240:

Inspección visual (especialista au

- Seite 241 und 242:

® Copyright ATH-Heinl GmbH & CO.KG

- Seite 243 und 244:

BEDIENINGSHANDLEIDING ATH M72

- Seite 245 und 246:

1.0 INLEIDING 1.1 Algemene informat

- Seite 247 und 248:

4 3 2 1 1 Druk het pedaal lichtjes

- Seite 249 und 250:

1.3.2 Afdrukken van een band Voorbe

- Seite 251 und 252:

Het schakelpedaal indrukken voor he

- Seite 253 und 254:

Na de demontage het schakelpedaal v

- Seite 255 und 256:

Bij de montage van de tweede hiel g

- Seite 257 und 258:

1.4 Technische gegevens Buitenste s

- Seite 259 und 260:

2.0 INSTALLEREN De machine mag uits

- Seite 261 und 262:

2.4 Opstellocatie De machine mag ni

- Seite 263 und 264:

2.8 Hydraulische aansluiting Voorda

- Seite 265 und 266:

3.0 GEBRUIK 3.1 Gebruikersinstructi

- Seite 267 und 268:

4.0 ONDERHOUD Om de machine veilig

- Seite 269 und 270:

4.3 Aanwijzingen De machine moet, o

- Seite 271 und 272:

4.6 Onderhouds- en servicehandleidi

- Seite 273 und 274:

REINIGEN VAN HET KLEPPENBLOK Kop

- Seite 275 und 276:

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 277 und 278:

6.2 Elektrisch schakelschema ® cop

- Seite 279 und 280:

7.0 GARANTIEKAART Dealernaam: Bedri

- Seite 281 und 282:

8.0 TESTBOEK Dit testboek (inclusie

- Seite 283 und 284:

8.2 Inspectieschema Typeplaatje Kor

- Seite 285 und 286:

Visuele inspectie (door geautorisee

- Seite 287 und 288:

Visuele inspectie (door geautorisee

- Seite 289 und 290:

® copyright ATH-Heinl GmbH & Co. K

- Seite 291 und 292:

INSTRUKCJA OBŁSUGI ATH M52

- Seite 293 und 294:

1.0 WPROWADZENIE 1.1 Informacje og

- Seite 295 und 296:

4 3 2 1 1 Wcisnąć pedał lekko w

- Seite 297 und 298:

1.3.2 Odbijanie opony Przygotowanie

- Seite 299 und 300:

Nacisnąć pedał w celu dociśnię

- Seite 301 und 302:

Po demontażu wcisnąć pedał, aby

- Seite 303 und 304:

Podczas montażu drugiej stopki nal

- Seite 305 und 306:

1.4 Dane techniczne Zakres zacisku

- Seite 307 und 308:

2.0 INSTALACJA Maszyna musi być za

- Seite 309 und 310:

2.4 Lokalizacja Maszynę należy tr

- Seite 311 und 312:

2.8 Przyłącze hydrauliczne Przed

- Seite 313 und 314:

3.0 PRACA 3.1 Instrukcja eksploatac

- Seite 315 und 316:

4.0 KONSERWACJA Aby zapewnić bezpi

- Seite 317 und 318:

4.3 Wskazówki Bez względu na zani

- Seite 319 und 320:

4.6 Instrukcje dotyczące konserwac

- Seite 321 und 322:

CZYSZCZENIE BLOKU ZAWOROWEGO Od

- Seite 323 und 324:

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 325 und 326:

6.2 Schemat obwodu elektrycznego ®

- Seite 327 und 328:

7.0 KARTA GWARANCYJNA Adres dealera

- Seite 329 und 330:

8.0 DZIENNIK BADAŃ Niniejszy dzien

- Seite 331 und 332:

8.2 Harmonogram kontroli Tabliczka

- Seite 333 und 334:

Kontrola wzrokowa (upoważniona oso

- Seite 335 und 336:

Kontrola wzrokowa (upoważniona oso

- Seite 337 und 338:

® Prawa autorskie ATH-Heinl GmbH &

- Seite 339 und 340:

NÁVOD NA OBSLUHU ATH M52

- Seite 341 und 342:

1.0 ÚVOD 1.1 Všeobecné informác

- Seite 343 und 344:

4 3 2 1 1 Jemne zatlačte pedál na

- Seite 345 und 346:

1.3.2 Odtlačenie pneumatiky Prípr

- Seite 347 und 348:

Spínací pedál na upnutie diskov

- Seite 349 und 350:

otáčavým pohybom rovnakým spôs

- Seite 351 und 352:

Pri montáži druhej pätky pláš

- Seite 353 und 354:

1.4 Technické údaje Vonkajšia ob

- Seite 355 und 356:

2.0 INŠTALÁCIA Stroj musí v súl

- Seite 357 und 358:

2.4 Umiestnenie Stroj by ste mali p

- Seite 359 und 360:

2.8 Hydraulické pripojenie Pred uv

- Seite 361 und 362:

3.0 PREVÁDZKA 3.1 Prevádzkový po

- Seite 363 und 364:

4.0 ÚDRŽBA Na účely zaistenia b

- Seite 365 und 366:

4.3 Upozornenia Na stroji je nutné

- Seite 367 und 368:

4.6 Návody na údržbu a servisné

- Seite 369 und 370:

ČISTENIE BLOKU VENTILOV Vedenia

- Seite 371 und 372:

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 373 und 374:

6.2 Schéma elektrického zapojenia

- Seite 375 und 376:

7.0 ZÁRUČNÁ KARTA Adresa odborn

- Seite 377 und 378:

8.0 KONTROLNÝ DENNÍK Tento kontro

- Seite 379 und 380:

8.2 Harmonogram kontrol Typový št

- Seite 381 und 382:

Zraková kontrola (povolanou odborn

- Seite 383 und 384:

Zraková kontrola (povolanou odborn

- Seite 385 und 386:

® Copyright ATH-Heinl GmbH & CO.KG

Unangemessen

Laden...

Magazin per E-Mail verschicken

Laden...

Einbetten

Laden...

LinkedIn

Facebook

Instagram

Youtube

Email

Twitter

Pinterest