ATH-Heinl Bedienungsanleitung M33

- Text

- Wwwathheinlde

- Rechte

- Urheberrecht

- Maschine

- Technische

- Tyre

- Manufacturer

- Assembly

- Technical

- Reserved

- Vorbehalten

2.9 Assembly These

2.9 Assembly These instructions are not to be viewed as assembly instructions; hints and tips are provided only for trained expert installers. Suitable clothing and personal protection must be worn for the following work. Incorrect installation and settings lead to exclusion of liability and warranty. Partly pre-assembled machines must be checked, introduced and approved by a competent person before commissioning. Machine assembly must be carried out by a qualified and competent person. 2.9.1. Securing the machine It is recommended that the machine is secured to the floor at the four points provided using M10 anchor screws and the corresponding dowels. Drill holes, observing the necessary drill depth A and drill diameter of the dowel manufacturer Clean out the inside of the holes Insert the anchor bolts into the holes until they have reached an appropriate depth. Tighten the nuts to the torque specified by the manufacturer Clamping thickness B varies depending on the floor covering 2.10 Completion of Work Before commissioning, check all fastening screws, electrical, pneumatic and hydraulic lines and, if necessary, tighten these. Warning: in some cases, this must be checked at regular intervals and tightened if necessary (note in the instructions). ® Copyright ATH-Heinl GmbH & Co. KG, All rights reserved / Misprints and technical changes reserved / As of: 2021-10 Manufacturer ATH-Heinl GmbH & CO.KG - 21 -

3.0 OPERATION 3.1 Operating Instructions Company: Place of work: Operation: Operating Instructions for Tyre Servicing Date: Signature: Risks to People and the Environment • Noise danger • Danger of being caught on machine • Danger due to uncontrolled moving parts • Danger from charged dust in the brake system Protective Measures and Rules of Conduct • Wear close-fitting clothes • Do not wear a watch, rings, chains or similar jewellery when working • Wear ear protection and safety goggles. • Longer hair should be secured by a hair net or other measure • Only use impact wrenches that don’t blow air on the wheel rim. • Clean wheels and tyres only when wet to avoid dust build-up; if possible, use wheel washing systems. • Remove dust on the brake drums with an extraction bell with suitable industrial vacuum cleaners. Use category U equipment for asbestos-free dusts and category K1 for asbestos-containing dusts. (Observe current GUV regulations) • Damaged tyres must not be used. • When inflating the tyre, set up a guard to catch any flying parts. Keep people out of the danger area. • Tyre filling must be monitored and the maximum permissible assembly air pressures must not be exceeded. • Only operate motor-driven wheel balancers with a protective hood. • For large wheels of trucks and self-driving machines: - On machines with vertical wheels, work with heavy tyres (for example, EM tyres) must be carried out by two people. - For tyres with a diameter >1.4 m or a weight >200 kg, fall-protection devices must be used. Response to faults and hazards • Machine defects must be reported to the manufacturer immediately • Switch off the machine and secure against unauthorised restart • Damage should only be repaired by qualified personnel First Aid • Inform first aiders (see alarm/emergency plan). • Treat injuries immediately. • Enter into the accident book • Contact emergency services for serious injuries. Emergency number:__________ Ambulance service: ____________ Maintenance • Repair only by instructed and trained persons • Disconnect or secure the machine from the mains power supply for set-up, adjustment, maintenance or servicing • Clean the machine after operation is ended • Annual check of the machine by an authorised and trained person ® Copyright ATH-Heinl GmbH & Co. KG, All rights reserved / Misprints and technical changes reserved / As of: 2021-10 Manufacturer ATH-Heinl GmbH & CO.KG - 22 -

- Seite 1 und 2:

Deutsch English Polskie Français

- Seite 3 und 4:

Inhalt 1.0 EINLEITUNG .............

- Seite 5 und 6:

1.2 Beschreibung 1 Handgriff mit Lu

- Seite 7 und 8:

1.3 Bedienung 1.3.1 Feststellen von

- Seite 9 und 10:

1.3.3 Aufspannen der Räder Vorbere

- Seite 11 und 12:

1.3.5 Demontieren eines Reifens Bei

- Seite 13 und 14:

Überprüfen Sie, ob sich der Monta

- Seite 15 und 16:

Stellen Sie sicher, dass der Reifen

- Seite 17 und 18:

1.5 Maßzeichnung ® Urheberrecht A

- Seite 19 und 20: 2.3 Lieferumfang 1 Stahlmontagekopf

- Seite 21 und 22: 2.5 Befestigung Hierbei sind die al

- Seite 23 und 24: 2.9.1 Befestigung Es wird empfohlen

- Seite 25 und 26: 3.2 Grundsätzliche Hinweise Mit de

- Seite 27 und 28: Druckluftanlage Mindestanforderung:

- Seite 29 und 30: 4.5 Fehlersuche / Fehleranzeige und

- Seite 31 und 32: KEILRIEMENSPANNUNG • In der Masch

- Seite 33 und 34: Einstellung der Antriebsriemenspann

- Seite 35 und 36: 6.0 ANHANG 6.1 Pneumatik-Schaltplan

- Seite 37 und 38: 6.3 Hydraulik-Schaltplan Nicht rele

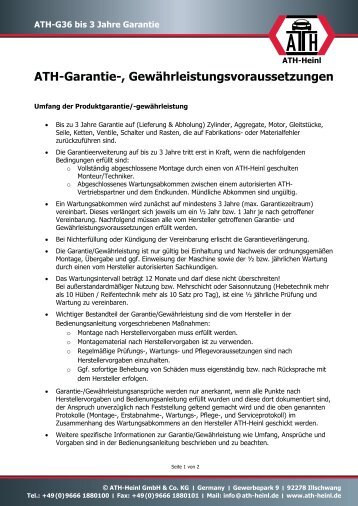

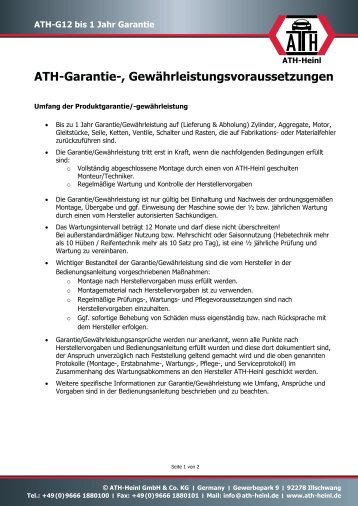

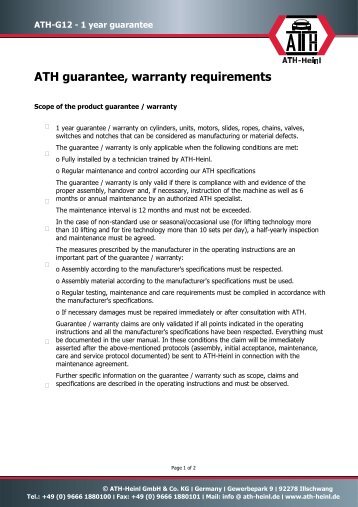

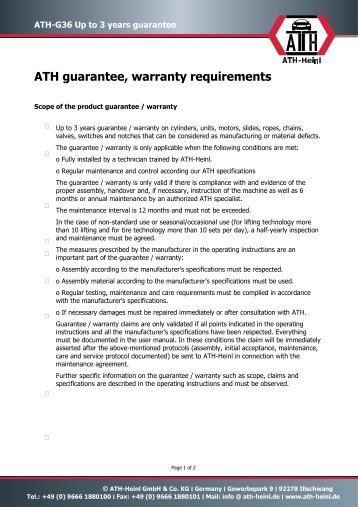

- Seite 39 und 40: 7.1 Umfang der Produktgarantie •

- Seite 41 und 42: 8.1 Aufstellungs- und Übergabeprot

- Seite 43 und 44: 8.3 Sichtprüfung (Befugte Sachkund

- Seite 45 und 46: Sichtprüfung (Befugte Sachkundige

- Seite 47 und 48: 9.0 NOTIZEN ® Urheberrecht ATH-Hei

- Seite 49 und 50: www.ath-heinl.de ATH-Heinl GmbH & C

- Seite 51 und 52: Contents 1.0 INTRODUCTION .........

- Seite 53 und 54: 1.2 Description 1 Handle with air v

- Seite 55 und 56: 1.3 Operation 1.3.1 Determining the

- Seite 57 und 58: 1.3.3 Clamping the wheels Preparati

- Seite 59 und 60: 1.3.5 Disassembling a tyre In princ

- Seite 61 und 62: Check whether the assembly head is

- Seite 63 und 64: 1.3.7 Inflating tyres The maximum t

- Seite 65 und 66: 1.5 Scale Drawing ® Copyright ATH-

- Seite 67 und 68: 2.3 Delivery Contents 1 Steel assem

- Seite 69: 2.6 Electrical Connection General a

- Seite 73 und 74: 4.0 MAINTENANCE The user must maint

- Seite 75 und 76: 4.3 Notes Regardless of the level o

- Seite 77 und 78: 4.6 Maintenance and Service Instruc

- Seite 79 und 80: CLEANING THE VALVE BLOCK • Separa

- Seite 81 und 82: 5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG

- Seite 83 und 84: 6.2 Electric circuit diagram ® Cop

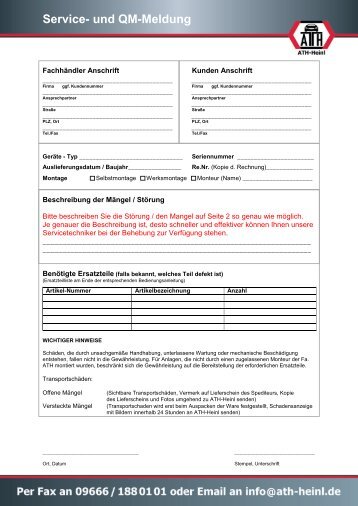

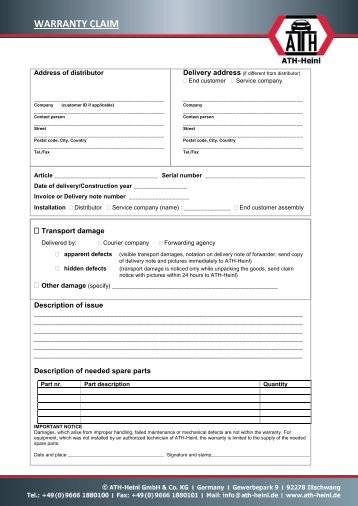

- Seite 85 und 86: 7.0 WARRANTY CARD Dealer address: C

- Seite 87 und 88: 8.0 INSPECTION LOG This inspection

- Seite 89 und 90: 8.2 Inspection Plan Nameplate Quick

- Seite 91 und 92: Visual inspection (authorised exper

- Seite 93 und 94: Visual inspection (authorised exper

- Seite 95 und 96: ® Copyright ATH-Heinl GmbH & Co. K

- Seite 97: www.ath-heinl.de ATH-Heinl GmbH & C

Unangemessen

Laden...

Magazin per E-Mail verschicken

Laden...

Einbetten

Laden...

LinkedIn

Facebook

Instagram

Youtube

Email

Twitter

Pinterest